Machine Molding

At the Nové Město nad Metují Foundry, we specialize in the mass production of gray and ductile iron castings. Using machine molding on FOROMAT equipment, we ensure efficient and precise casting production across various weights, with a strong emphasis on the quality and reliability of each piece.

- Nové Město nad Metují Foundry

Molding with Bentonite Mixture

This method is ideal for castings with weights ranging from 0.1 kg to 120 kg, with the exception of piano frames, where the maximum weight can reach up to 230 kg. The bentonite mixture is prepared in a wheel mixer and then distributed to individual workstations, where it is compacted into a molding frame. After the model device is removed, the mold is thoroughly cleaned with compressed air, and if necessary, cores are installed before moving to the casting field. We use aluminum and steel (sheet metal) molding frames with sizes ranging from 500 x 300 x 160 mm to 3000 x 1800 x 230 mm, which allows us to adapt to a wide range of requirements. Typical products of this technology include castings for channel elements, piano frames, and rope pulleys.

Molding with Self-Hardening Inorganic Geopolymer Mixture

This technology is suitable for more technologically demanding and heavier castings with weights ranging from 30 kg to 500 kg. The molding mixture is prepared in a continuous SPARTAN 5P mixer and is directly poured into molding frames, which have dimensions ranging from 580 x 580 x 390 mm to 1750 x 1200 x 200 mm. After partial hardening, which takes about 60 minutes, the molds are disassembled and left to cure until the next day. The following day, the molds are coated with a graphite alcohol-based coating and prepared for casting. After casting and cooling, the mold is disassembled, and the residual mixture is regenerated for further use. This method is mainly used for the production of castings for printing machines.

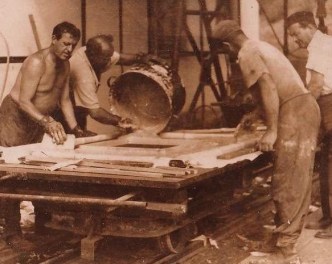

Thanks to the variability of the molding frame dimensions and the selection of self-hardening geopolymer or bentonite mixtures, we are able to respond flexibly to the different needs of our customers. Hand molding in our foundry allows the production of high-quality castings in small series or individual pieces.

Hand Molding

Hand Molding Melting device

Melting device Agricultural Machines

Agricultural Machines Traffic devices

Traffic devices_0x265.jpg)