-

More Than 100 Years

Founded in 1912 by Jan Rousek and his sons, the foundry in Nové Město nad Metují builds on a long-standing tradition of producing castings from grey and ductile iron using machine and hand molding into bentonite mixtures and water glass.

Flexibility

Flexibility in the size of molding frames, as well as dual sand preparation (chemically bonded water glass and bentonite), allows us to respond precisely to our customers' specific requirements, while tradition and quality remain our core values.

-

We Ensure Quality

To establish and maintain a long-term relationship with our customers, the mechanical and physical properties of the castings, as well as the aesthetic quality of the surfaces, are key. Every grey and ductile iron casting undergoes strict quality control at the foundry.

Inspection

Quality control includes visual inspection, dimensional measurements, mechanical property testing, and chemical analysis. Our laboratory is equipped with modern instruments for spectrometric and mechanical tests, ensuring maximum accuracy of results. We take full responsibility for the quality of the produced castings.

-

Individual Approach

Our foundry builds on a strong partnership with the customer. Together, we go through the entire process of sampling castings, preparing model creation, checking molding and casting technology, verifying materials and casting dimensions, and finally producing castings from grey and ductile iron.

Collaboration

Mutual collaboration is key to achieving the optimal quality of castings and meeting the customer’s requirements, ensuring long-term cooperation. We are happy to visit the customer’s production facilities to better understand their needs and tailor our solutions to specific demands.

-

Environment

The foundry places great emphasis on ecology and environmental responsibility in the production of grey and ductile iron castings. We actively reduce emissions and adhere to sustainable standards, protecting our community.

ESG Standards

Responsibility in line with ESG standards is important to us, as is economically efficient and effective production. We focus on innovations that improve the quality of our castings while minimizing negative impacts on nature.

-

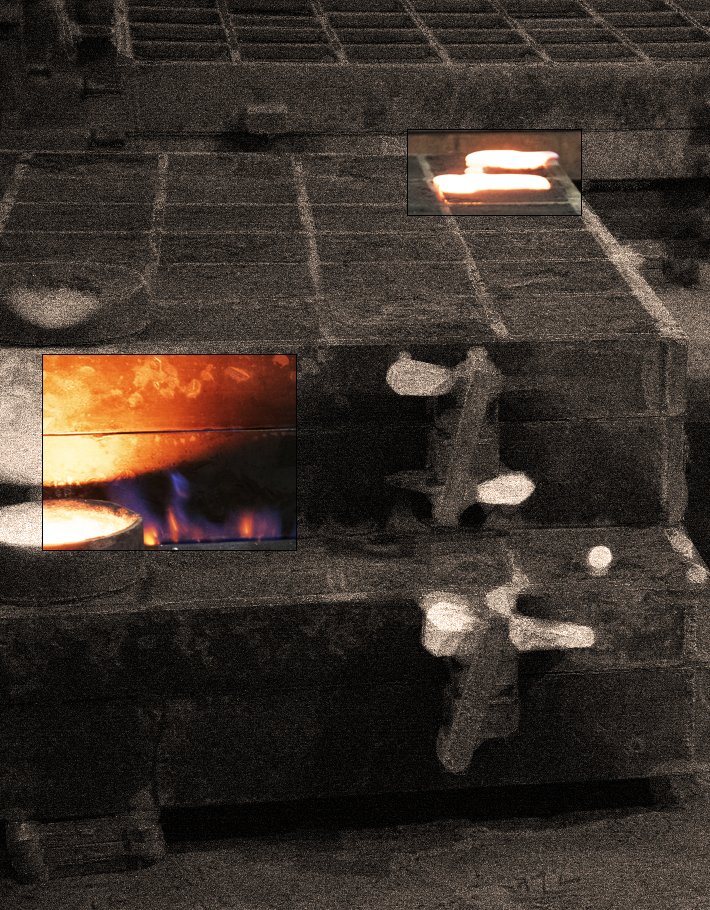

Production of quality castings

Hot performance